Expertise in Blast Furnace Refractory Relining

Who We Are and Why Our Expertise Matters

Our journey began in 2010 with the establishment of Seven Refractories d.o.o., a fast-growing company specializing in the production of high-quality refractory monolithic materials and green resin-bonded taphole clay for blast furnaces.

As our clients’ needs evolved, it became essential to offer a complete package: engineering, materials, and installation services. Soon, we expanded into maintenance of reheating furnaces, runners, ladles, and many other refractory field, led us to develop the equipment and skilled teams required for blast furnace refractory relining.

After fifteen years of working inside blast furnaces, improving our installation techniques and upgrading our equipment, we are proud of our achievements and confident in calling ourselves a top player in blast furnace repairs.

In 2023, Seven Refractories was acquired by RHI Magnesita GmbH, a global leader in refractory products, solutions, and installation equipment—making us part of the number one company in the industry.

Starting in 2026, the installation department of the former Seven Refractories became a new, independent company dedicated exclusively to installation services: Sipra Service d.o.o., established in partnership with our Italian sister company Sipra S.p.A., a strong and experienced installation provider. This merger allows us to offer our clients not only in the steel industry but across any sector requiring refractory products a high-quality maintenance and installation service.

Contact us today—it's free of charge! 😉

Our Key Services

Delivering excellence through specialized services.

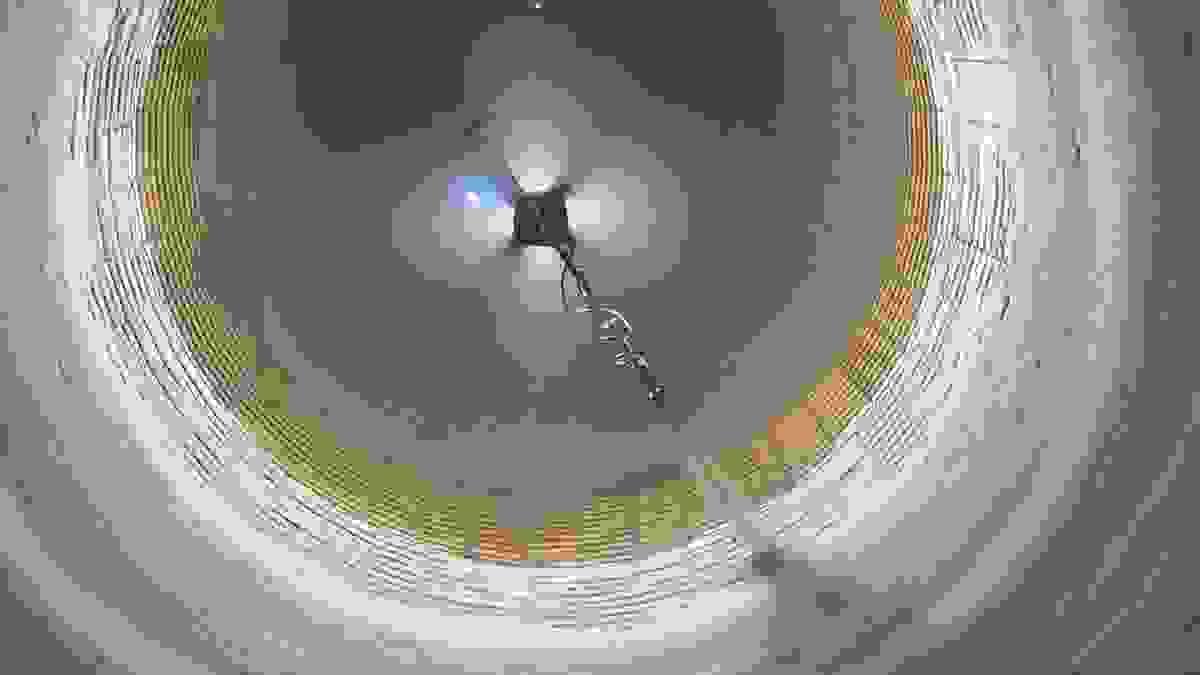

Robotic Blast Furnace Relining

We deliver specialized blast furnace relining services using advanced robotic systems and shotcrete materials, maximize efficiency and significantly reduce installation time.

Our experienced team operates and monitors the entire process remotely from a secure control room, ensuring safety from dust, fumes, and toxic gases while maintaining optimal working conditions regardless of external weather.

Precision installation ensures structural integrity, long-term durability, and optimal material performance with wery low rebound. This includes perfect sealing around cooling elements and achieving a smooth furnace surface.

Upon completion, the furnace could be restored to operational status in full compliance with original design specifications.

Manual Blast Furnace Relining

We are also highly experienced in manual blast furnace relining, working inside the furnace using dedicated scaffolding or movable platforms.

This approach significantly improves installation speed, minimizes furnace downtime, and ensures a safe, efficient process.

Our skilled nozzle operators guarantee perfect sealing of any furnace irregularities, residual wear, or gaps around the interior, leaving the furnace with a smooth surface and meeting precise relining thickness requirements.

By working in double shifts without interruption, the installation proceeds quickly and without material waste caused by unnecessary cleaning. Continuous application prevents dry joints between shotcrete layers installed at different times.

Fast, efficient, and safe!

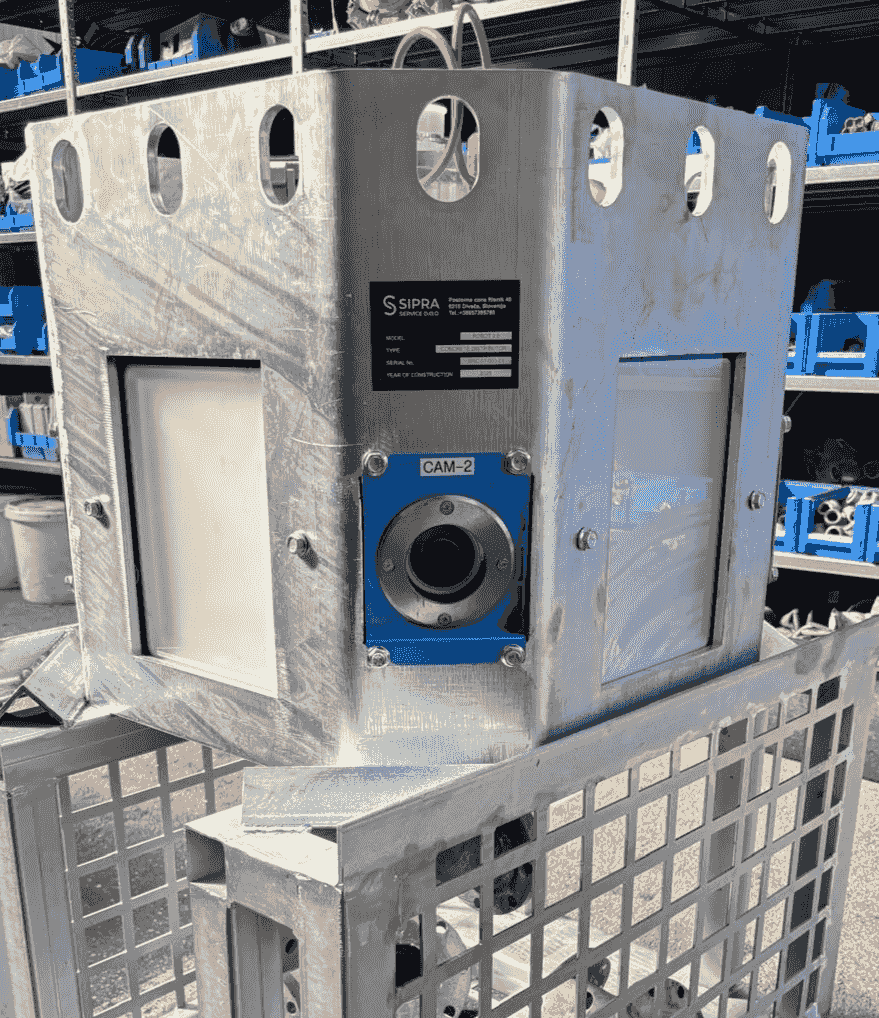

Custom Equipment Design

We create custom equipment for optimal installation processes, aligning with your specific requirements.

Examples:

- Blast furnace robots

- High performance 1 ton padle mixers

- Gunning machines

- Double piston pumps for refractores purplose

- Hot Grauting injection machines

- Feeding silos

- Different tools and small equipoment

Our commitment to innovation ensures that each design enhances operational efficiency and meets the highest industry standards, providing you with reliable solutions tailored to your unique challenges.

Our Recent Projects

Highlights of our latest successful installations.

Our Mission

To provide our costumers top-tier refractory installation services, and solution ensuring maximum efficiency and safety in steel plants operations, especialy reducing a furnace downtime.

Our Expertise

15 years of experience in the industry, our team comprises specialists in refractory materials and equipment design.

Our Commitment

We are committed to delivering high-quality solutions and unparalleled customer service, tailored to meet the needs of our clients.

©2026 - Proudly built with Strikingly